As defined in our previous article about different types of torque wrenches, a torque wrench applies the required amount of torque on a fastener i.e. a nut to either tighten or loosen it. However, there are many factors involved that deteriorate the life of these fastening tools. Based on experience in the industry, we have collated a list of common problems leading to tool failure or breakdown. Also, we will be sharing some preventive measures that can reduce maintenance costs.

Why does a torque wrench break?

1. Incorrect application study

It is very important to understand the application of the tool and design a customized solution based on that. The application study is important to understand multiple factors to recommend the right tool and components to complete the job swiftly without incurring any breakdown.

2. Side load

Side load is generated when the tool is incorrectly fit to the stud. It commonly occurs due to lack of training or incorrect application study. Side load does not damage the tool immediately but due to constant side load, the tool can breakdown in the long run. Unnecessarily side loads over extended periods of time damage the tool housing.

3. Incorrect reaction arm positioning

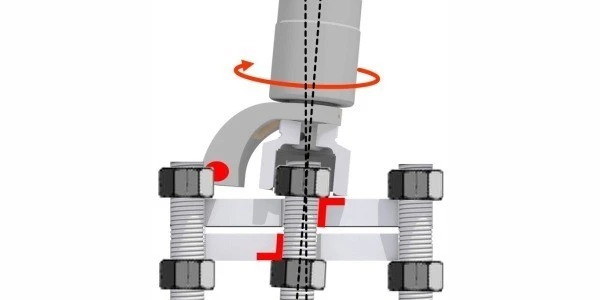

As Newton’s 3rd law states, every action requires an equal and opposite reaction. Taking that into consideration, when applying torque output, a torque wrench requires a reaction arm that would lock itself at an adjacent point. In doing so, a standard torque wrench will try to align itself so that the action axis (torqueing axis or bolt axis) and the reaction axis should be parallel and on the same plane.

With development in technology, some torque wrenches can be used without a reaction arm with the help of special accessories. When a torque wrench is used with such accessories, it will have a coaxial reaction (bolt axis and reaction axis). A coaxial reaction axis is recommended as it eliminates the pinch point and side load. Keeping the fingers of operators safe and tools safe.

4. Improper storage or handling

Common problems noticed due to improper handling are that the tools are not cleaned after use. It is important to clean it regularly after use as dirt and debris from previous usage can eventually wear off the tool. Another issue dealt is improper handling, technicians often pull hoses to adjust the tool while in operation or to lift the tool. This might damage the seals of the swivel post. We would recommend using a tool handle for easy handling and to keep the operator’s fingers away from the pinch point or reaction point as a safety measure. It is important to ensure that every tool should have a delegated case and a delegated location for easy access and storage.

Measures required to safeguard a torque wrench

1. Application study

A correct application study can resolve 40% of tool breakdown cases. It is very important for a site engineer to understand the application before suggesting the right tool. Wrong tool can not only damage the application, but also be an economical loss for the customer.

An application study involves understanding the industry, type of application, availability of space, and torque requirement to name a few. These factors help recommend the most appropriate tool and also understand if any additional customized accessories are required.

2. Tool Training

Tool training is very important. It not only trains the customer on the safety aspects of the tool but also on how to use the tool appropriately to avoid side load and other tool failure issues. Training can help reduce maintenance costs by improving the life of the tool. Training is also important to handle the tools appropriately to avoid pinch points.

3. Annual Tool Maintenance

Annual tool maintenance does not only mean repairs but also includes tool auditing and calibration which checks on the health of the tool. Auditing helps understand any problems in the tool and rectify it as soon as possible. Similarly, tool calibration checks the accuracy of a torque wrench. As tools age, its accuracy deters. Therefore, it is important to audit and calibrate tools for optimized performance.

We hope this article has helped you take some preventive measures on treating your tool right. Visit us next time for more knowledge sharing articles.